|

|

Процесс изготовления Мокуме от Ariel Salaverria с www.bladeforums.com

This is a more complete tutorial on how to make mokume, I hope you enjoy!

Any questions, please feel free to make them and I'll answer them to the best of my knowledge.

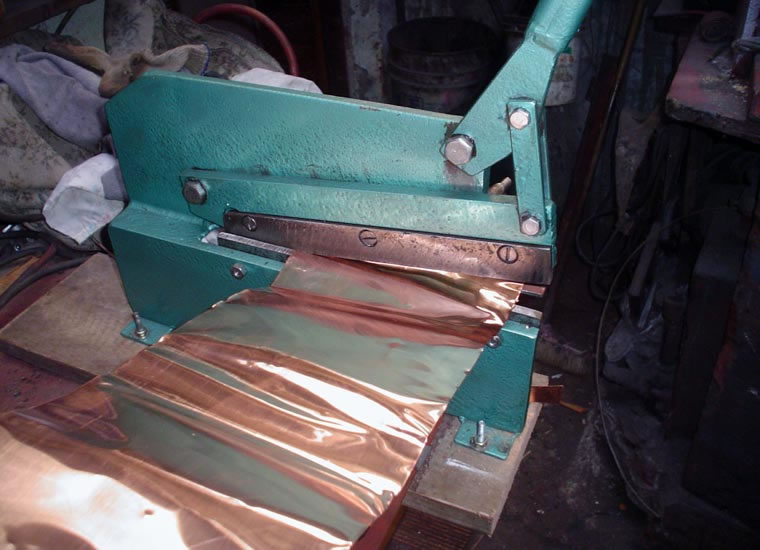

Cutting copper layers (0.25mm thick) into 32 x 200mm rectangles.

All layers of metal (copper, 1010 and 1070) and the cannister.

Placing the metal strips into a square section cannister of 1.5mm thickness. The first and last strips are 0.5mm thickness stainless 304 to prevent welding against the cannister inner walls.

Closing the cannister.

Placing it on the oven at 1200C for 15 minutes.

Pressing it.

Cannister after being pressed.

Still hot. With some pliers I break the cannister. (15-20 minutes after being pressed. I just drop it on the workshop floor for that time, so it's still hot)

Stainless strip.

After taking the welded piece off the cannister (half ingot) I make some cuts to get it to draw some more.

After making the cuts, I place it on the oven at 200C and leave it there til it reachs 850C (about 10 minutes total time) and then I press the ingot again til it reachs about 8mm thickness, so after grinding it has 6mm.

After grinding it I etched it and this is how it ended up looking.

Other similar work.

Thanks for looking!

Ariel

Взято с bladeforums.com