|

|

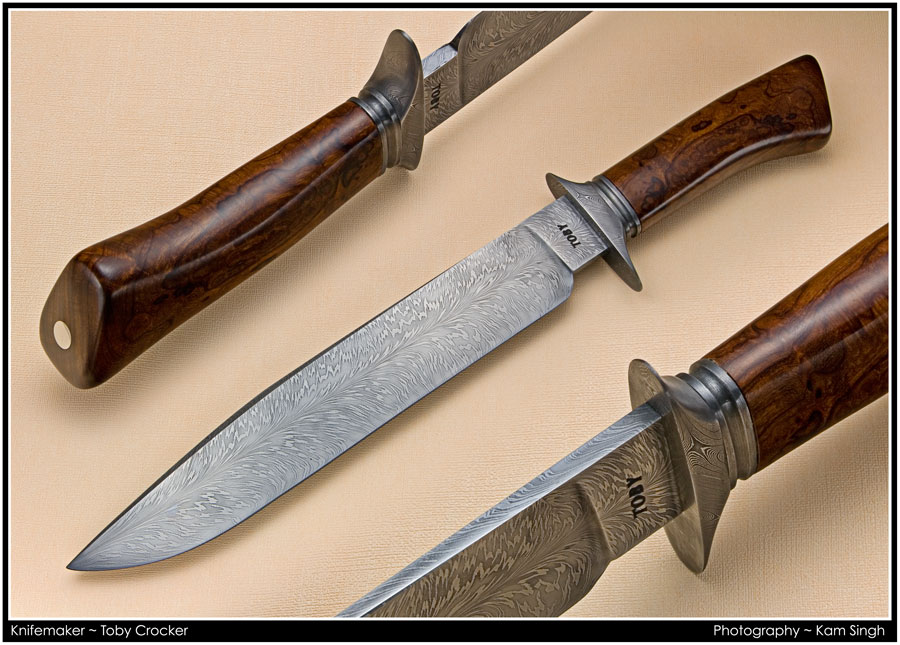

Toby Crocker feathered damaskus

Взято с сайта Тоби Крокера tobyknives.com

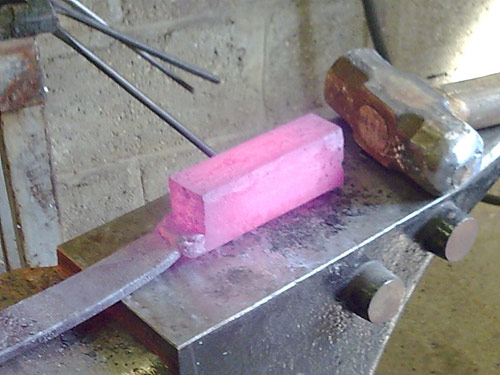

First start with 11 layers of steel, C20 and 15n20.

Weld it up then turn it through 90deg(has been forged out a little)

Drawn out to twelve inches by about 3/8-1/2" thick then sectioned out into four bits ready for the first stack

Stack ready for welding.

All welded up - now just got to do this all over another three times.

After all that stacking and welding the billet is sectioned into six...

...and stacked up ready for welding.

Billet all welded up - this is our W's made.

Billet all cleaned up - VERY important to keep a reference of where everything is at All times as it is so easy to mess everything up all the way to the end of the process.

Handle has been moved to the side and our precious billet of W's has been hacked into nearly two with a very blunt cutter(about 4mm thick at cutting edge).

Handle moved again then welded it back up into one block again (make sure you do EVERYTHING at welding temperature) i didn't have it hot enough when closing up the two sides and started to open up a weld - managed to stop it and weld it back up, but best to do it right first time!

The billet has been drawn out to 7 1/2" long by 3/8" thick by 1 1/2" wide, and is now cooling on the forge floor.

Billet after it has been etched.

The billet is still a bit compressed and will spread out a bit yet when it is drawn out.

Knife made from this billet:

Взято с сайта Тоби Крокера tobyknives.com