| KnifeHelp/ Blacksmith practice ENG |

Взято с www.metalwebnews.com BLACKSMITHING EQUIPMENT; FORGE FIRES Whether a farmer can afford a forge and anvil will depend upon the distance to a blacksmith shop, the amount of machinery repair work he needs to do or have done, and his ability as a mechanic. Although not every farmer can profitably own blacksmithing equipment, many farmers can. If a farmer cannot, he should remember that a great deal of repair work can be done with cold metal, if he has a few simple tools like a vise, a hack saw, files, cold chisels, and drills.

Although blacksmithing under many conditions should occupy a minor place in a farm shop course, no such course can be considered complete without at least some instruction in this work. Blacksmithing is generally more difficult than woodwork. Almost any high school boy with average mechanical ability, however, can soon learn to do simple blacksmithing and feel well repaid for his efforts, if he will set himself diligently to the task. In all mechanical work, much more rapid and satisfactory progress can be made if the student will carefully study the theory and principles along with his practice. This is particularly true of blacksmithing.

276. The Forge.-The forge for the farm shop should have a gear driven blower operated by a crank, and it should have a hearth at least 18 in. wide, preferably somewhat larger. Probably the cheapest way of providing a good forge is to buy a good blower and tuyere (that part in the bottom of the hearth through which the blast comes) and make a hearth and stand of concrete, brick, or other masonry. The forge should be provided with a hood and pipe connection for taking away the smoke.

277. The Anvil.-Anvils are of two general grades: cast iron and steel. Steel anvils are much better and should be used if they can be afforded, The two kinds can be distinguished by striking with a hammer. A cast anvil has a dead sound while a steel one has a clear ring.

Anvils are commonly available in sizes ranging from 50 to 200 lb. An anvil weighing 100 or 125 lb. would be quite satisfactory for the average farm shop. A piece of railroad iron 20 to 30 in. long, mounted on a suitable block or stand, will serve fairly well for light hammering and riveting, although a much greater variety of work can be done on a regular anvil.

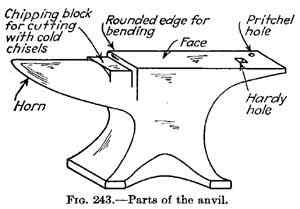

Use of Different Parts of Anvil.-- The horn of the anvil is used for making bends and shaping curved pieces; and the flat face is used for general hammering. The flat depressed surface near the horn is the chipping block, and here all cutting with cold chisels and similar tools should be done, rather than on the face of the anvil. The chipping block is soft and will not damage the chisel if it cuts through. The face is hardened and cutting into it with a chisel would damage both the chisel and the face, which should be kept smooth for good blacksmithing.

The better anvils have a comer of the face next to the horn slightly rounded, so that sharp bends may be made in rods and bars without unduly marring or galling the iron. The round hole in the face of the anvil is used for punching holes. It is called the pritchel hole, taking its name from the sharp punch used by smiths in punching nail holes in horseshoes. The square hole in the face is called the hardy hole and is used for holding the hardy and other tools, such as swages and fullers.

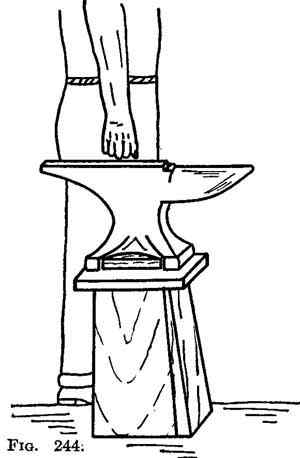

Mounting the Anvil. -- The anvil should be mounted on a solid block, preferably of wood. It should be so located in front of the forge that the workman can take the irons from the fire and place them on the anvil by making a short turn and without the necessity of taking even a full step. The horn should be to the workman's left (unless he is left-handed, in which case it should be to his right). The face of the anvil should be at such a height that it can be touched with the knuckles of the clenched fist when standing erect and swinging the arm straight down.

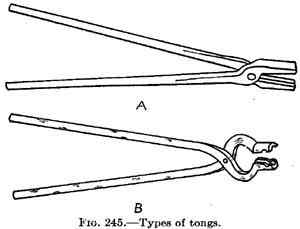

278. Tongs.-At least one or two pairs of tongs will be needed. Various types are available, but the hollow-bit, curved-lip bolt tongs are probably the most useful. Flat bars as well as round rods and bolts can be held in them, and the curved part back of the tip makes it possible to reshape them easily to fit different sizes of stock. By grinding, filing, or sawing a groove crosswise in each of the lips, the tongs can be made to hold links practically as well as regular link tongs (see Fig. 245). Tongs 18 to 20 in. long are a good size for average work.

279. Hammers.-A blacksmith's hand hammer weighing 1 1/2 or 2 lb. and another weighing 3 or 3 1/2 lb. will handle all ordinary work very satisfactorily.

280. Hardy, Chisels, Punches.-There should be a hardy to fit the hole in the anvil, and there should be a fair assortment of hand cold chisels and punches. The chisels and punches may be made in the shop. If considerable blacksmithing is to be done, it would be well to have a hot cutter and a cold cutter (simply large chisels with handles on them) for heavy cutting with a sledge hammer. It would be well, also to have one or two large punches with handles on them for punching holes in hot metal. Punches for making holes 3/8 in. and 1/2 in. in diameter are probably most useful.

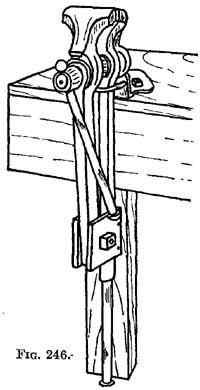

281. Vise.-One vise can well serve for all metal work in the farm shop, including blacksmithing if it is heavy and strong enough. A heavy blacksmith's steel-leg vise with jaws 4 to 5 in. wide is generally preferred as an all-purpose vise in the farm shop. A leg vise is one that has one leg extending down to be anchored or fastened into the floor. Such a vise can be used for heavy hammering and bending better than other types. If there is a strong steel machinist's box vise in the shop, it can be used for blacksmithing work if care is used not to do too heavy hammering or bending with it.

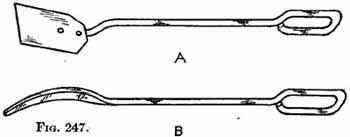

282. Fire Tools.-A small shovel and poker or rake will be needed for use on the forge fire. These can easily be made in the shop. A flat piece of heavy sheet iron about 3 or 4 in. wide by 4 or 5 in. long, riveted to a bar or rod for a handle, makes a good shovel. A 1/2-in. round rod,with an oblong eye in one end to serve as a handle and the other end flattened and curved, makes a good combination poker and rake.

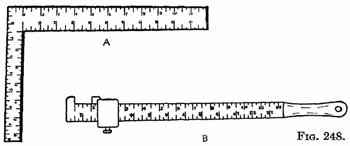

283. Measuring Tools.-Some kind of metal rule will be needed for measuring and checking pieces being forged. A small steel square is very good for both measuring lengths and checking angles and bends. A wooden rule should not be used to measure hot iron. A caliper, or a caliper rule, for measuring diameter of rods and thickness of parts, although not a necessity, will be found very convenient.THE FORGE FIRE A good fire is the first requirement for good blacksmithing. Many beginners do poor work simply because they do not recognize the importance of a good fire.

A good forge fire has three characteristics. It is clean, that is, free from clinkers, cinders, etc. It is deep, with a big center of live burning coke. And it is compact, being well-banked with dampened coal.

284. Fuel for the Forge Fire.-Blacksmithing coal is used in the forge. It is a high-quality soft coal that is practically free from sulphur, phosphorus, and other objectionable impurities. When dampened and packed down around the fire, it readily cakes and changes to coke, which is a lightweight material that burns with a clean, intense flame. Ordinary stove or furnace coal will not work satisfactorily in a forge.

285. Building the Fire.-To start a fire, first clean the fire bowl with the hands, pushing all coal and coke back on the hearth and throwing out all clinkers. Clinkers are heavy and metallic and have sharp, hard corners or projections and are therefore easily distinguished from the coke, which is light in weight and easily crumbled. Fine cinders and ashes are easily shaken through the grate into the ashpit.

After cleaning the fire bowl, dump the ashpit below the tuyere and then try the blower and make sure a good strong blast comes through. Sometimes ashes work back into the blower pipe and obstruct the blast.

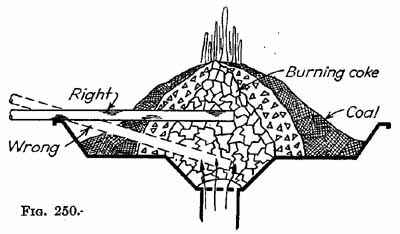

Next light a small handful of shavings or kindling from the bottom and drop onto the tuyere. Give the blower a gentle turn and rake fuel, preferably coke left from the previous fire, onto the burning kindling. Once the fire is burning well, rake more coke onto it, and bank the fire on both sides and on the back with dampened coal. This forms a mound with burning coke at the center, and the heat is concentrated in the center by the dampened coal on the outside. In a little while this dampened coal, sometimes called green coal, has gases driven off and it changes to coke.

286. Maintaining the Fire.-When the coke at the center of the fire burns up, additional coke from the hearth or the underside of the mound is forced into the center, and from time to time green coal is added to the outer parts of the mound to keep the fire well banked. Do Dot continually poke at the fire; simply keep the center well supplied with coke and the outside packed down with dampened coal.

If the fire tends to spread too much or becomes open and loose, throw or sprinkle water on the edges and pack it down with the shovel. Only a gentle blast of air should be used. Excessive air makes an oxidizing fire and causes the iron to scale badly.

287. Cleaning the Fire.-From time to time-usually every half hour when welding-the clinkers and cinders that accumulate over the tuyere should be removed. This can be done by passing the shovel along the bottom of the hearth to the center of the fire and then raising it straight up through the fire. The clinkers can then be easily seen and removed. Most of them will stay on the shovel. The burning coke is then raked back into the center and the outside packed down, using green coal on the outer edges if needed.

288. Heating the Irons.-To heat irons in a forge, they should be placed in the fire in a horizontal position, not pointing down. There should be burning coke below the irons, on both sides of them, and on top of them. Irons heated in a deep, compact fire heat much more rapidly and oxidize or scale off less than when heated in a shallow, burned-out fire. Some scale will form in spite of a good fire, but it should be kept to a minimum. A good blacksmith keeps the scale brushed from the face of the anvil with his hands.

Small thin parts heat much more rapidly than heavier and thicker parts. To prevent burning the thinner parts, they may be pushed on through the fire to a cooler place, or the position of the irons otherwise changed to make all parts heat uniformly. Mild steel should be heated to a good, bright-red heat for forging. It should not be allowed to get white hot and sparkle, as it is then burning.

289. Fitting Tongs; Holding the Work.-If tongs cannot be found to fit the work, a pair should be reshaped by heating and hammering the jaws over the piece to be held. Poorly fitting tongs are a source of continual trouble and should not be used.

Some Work Done without Tongs.-A considerable amount of work can be done without tongs. An eyebolt, for instance, can be made on the end of a rod 20 or 30 in. long and then cut off when finished.

Questions 276. (a) What is the cheapest way of providing a good forge for the farm shop? (b) What kind of blower would you recommend? (c) How large a hearth should the farm forge have?

277. (a) What different kinds of anvils are available? (b) What kind is best, and how may the different kinds be readily distinguished? (c) What size of anvil is best for the farm shop? (d) Can a piece of railroad iron or rail be used satisfactorily in the farm shop? (e) What is the chipping block and what is it for? (f) Why is one corner of the anvil face rounded? (g) What is the purpose of the holes in the face? (h) In what position should the anvil be mounted with respect to the forge? (i) How high should it be mounted?

278. (a) What kind or kinds of tongs would you recommend for the farm shop? (b) What size?

279. What sizes of hand hammers would you recommend for blacksmithing?

280. What other tools, like hardies, chisels, and punches, would be needed?

281. What kind and type of vise is best for blacksmithing?

282. (a) What fire tools -will be needed? (b) What materials would be needed to make these in the shop? I

283. (a) What measuring tools would you recommend for blacksmithing? (b) In what respects is a small steel square better than a rule? (c) Why are wooden rules not satisfactory?

284. (a) What are the characteristics of a good forge fire? (b) What kind of fuel is used in the forge? (c) What are its characteristics or properties?

285. (a) Just how would you go about building a fire in a forge? (b) Why should the fire be well banked with green coal?

286. (a) What attention should the fire have to keep it in good condition? (b) How may it be kept from spreading or becoming open and loose?

287. (a) How often should the fire be cleaned? (b) Just how is the fire cleaned?

288. (a) Just how should the irons be placed in the fire? Why? (b) How may light or thin parts be kept from overheating? (c) How hot should irons be heated for forging?

289. (a) How may tongs be reshaped to fit the work? (b) Under what conditions may work be done without tongs?

References SCHWARZKOPF: "Plain and Ornamental Forging."

RADEBAUGH: "Repairing Farm Machinery."

FRIESE: "Farm Blacksmithing."

HARCOURT: "Elementary Forge Practice."

Boss, DENT, and WRITE: "Mechanical Training."

CHAPTER XIX

FUNDAMENTAL FORGING OPERATIONS

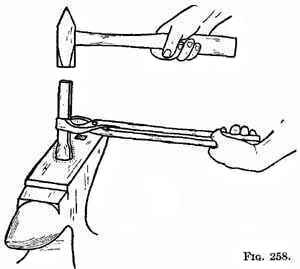

Forging may be defined as changing the shape of a piece of metal by heating and hammering. All the various operations that a blacksmith performs in forging iron may be classified into a surprisingly small number of fundamental or basic processes. Once these are mastered, the beginner is well on his way to success, and he can do practically any ordinary piece of forge work. These fundamental operations are (1) bending and straightening; (2) drawing, or making a piece longer and thinner; (3) upsetting, the opposite of drawing, or making a piece shorter and thicker; (4) twisting; and (5) punching. Other operations commonly done by a blacksmith, but which are not strictly forging, are welding, tempering, drilling, threading, filing, etc.290. Bending and Straightening.--In bending at the anvil, two things are most important:

1. Heat the iron to a good bright-red heat, almost but not quite white hot, throughout the section to be bent.2. Use bending or leverage blows-not mashing blows.

The iron should be so placed on the anvil and so struck that it can bend down under the hammer blow without being forced against the anvil and mashed. If the iron is struck at a place where it is resting firmly on the anvil, it will be mashed instead of bent. A few moderately sharp blows are better than several lighter blows.

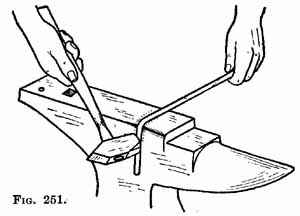

Abrupt square bends can be made over the face of the anvil near the chipping block where the corner of the anvil is rounded to prevent marring or galling the iron.

Care should be taken to keep the iron at the proper bending heat. If it gets below a red heat, it should be put back in the fire and heated again. To bend a piece at a certain point, without bending the adjacent section, the piece may be heated to a high red heat and then quickly cooled up to the point of bending by dipping in water. Bending is then done quickly by hammering, or other suitable methods.

Bending may be accomplished in several ways besides hammering over the anvil. The iron may be heated and then put in the pritchel or hardy hole and bent by pulling; or it may be clamped in a vise and bent.

Straightening can usually best be done on the face of the anvil. The stock should always be firmly held and then struck with the hammer at points where it does not touch the face. Sighting is the best way to test for straightness and to locate the high points that need striking.

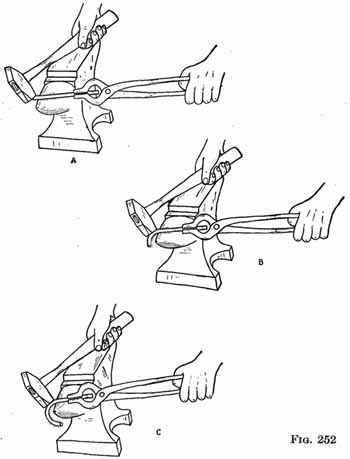

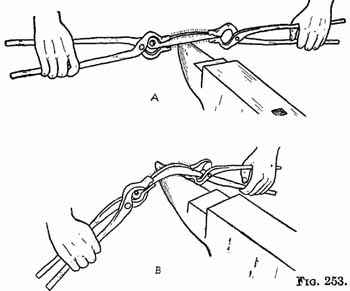

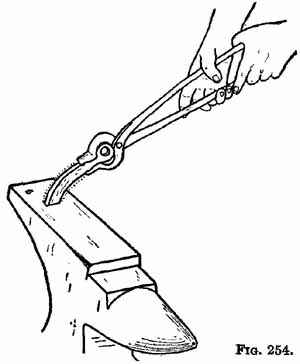

Bending Flat Bars Edgeways.-A flat bar can usually be easily bent edgeways by heating and placing over the horn and bending the two ends down slowly, using the hands if the piece is long enough, or two pairs of tongs in the case of short pieces (see Fig. 253). Sometimes the bending can be done easily by putting one end of the piece in the hardy hole and pulling on the other end (see Fig. 254). If the stock starts to buckle, it should be laid flat on the anvil and straightened. Hammering the outside edge of the iron when laid flat will tend to stretch it and therefore help with the beading. Once the bend is well started, hammering the piece on edge around the horn is not so difficult. The stock should always be firmly held, either by hands or with tongs, and the parts to be bent should be at a high red heat. Places not to be bent should be comparatively cold.

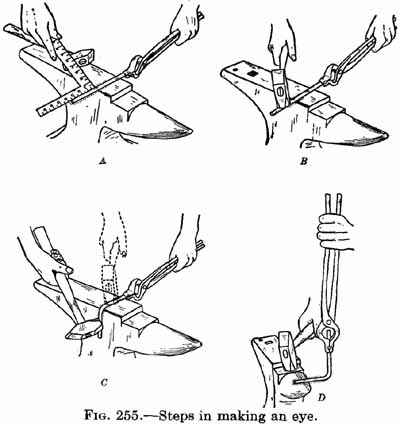

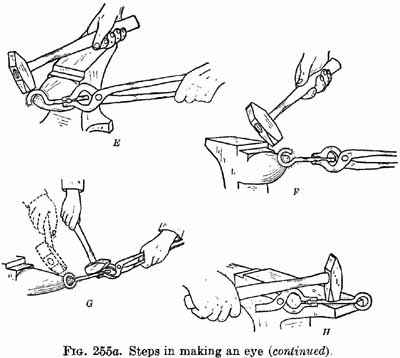

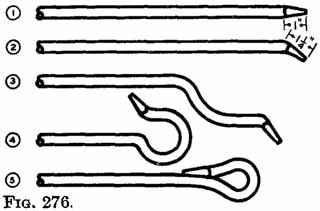

291. Bending and Forming an Eye.-One of the most common bending jobs in the blacksmith shop is that of forming an eye on the end of a rod. The following is a good method of making such an eye:

1. Heat the rod to a good red heat back for a distance of about 5 to 8 in., depending on the size of the eye.2. Quickly place the rod across the face of the anvil with just enough of the heated end projecting beyond the edge of the anvil to form the eye. For exact work the length of hot iron that is to project over may be quickly measured with a metal rule. The iron should be placed across the anvil well up near the horn where the edge is rounded.

3. Bend the end down, forming a square bend, with a few well-directed blows. Work rapidly before the iron cools.

4. Heat the end of the stock and start bending the. tip end around the horn. Work from the tip back toward the stem. Keep the iron hot throughout the part being bent; otherwise the bending will be slow and difficult, and the iron will not bend at just the places desired. If the square bend at the juncture of the stem and eye tends to straighten out, it is an indication that the end of the stock is not being kept hot enough while being bent.

5. Round the eye by driving it back over the point of the horn, noting carefully where it does not rest against the horn and striking down lightly in these places. Keep the iron well heated.

6. Center the eye on the stem, if necessary, by placing the stem flat on the anvil face with the eye projecting over the edge, and striking the. eye. The stock should be well heated at the juncture of the stem and eye, but the eye itself should be practically cold. Such a condition can be produced by heating the whole eye and then quickly cooling most of the rounded part by dipping in water.

292. Drawing.-Drawing is the process of making a piece longer and thinner. Two important points should be kept in mind while drawing:

1. The iron must be kept at a good forging heat, a high red or nearly white.2. Heavy, straight-down, square blows should be struck.

Many beginners make the mistake of striking a combination down-and-forward pushing blow, thinking that the pushing helps to stretch the metal.

A. Place a well-heated iron across the anvil with. enough stock projecting over -to form the eye. Where the eye must be made accurately to size, use a metal rule or square for measuring. Work rapidly. IB. Bend the projecting portion down, forming a right angle.

C. Finish the right angle bend by striking alternately on top and on the side, keeping the iron at a good working heat all the while.

D. Start bending the tip end around the horn, being careful to strike "overhanging" or bending blows.

E. Gradually work back from the end to the square bend.F. Turn the eye over and close it up. Exert considerable back pull on the tongs to keep the upper part of the eye up off the horn. In this position the hammer can strike bending blows instead of flattening or mashing blows.

G. Round the eye by driving it back over the point of the horn. Carefully note where the eye does not touch the horn, and strike down lightly in these places.

H. To straighten the stem of an eye, place it across the corner of the anvil face and strike the high points while the iron is at a good working heat.

Drawing can be done more rapidly over the horn than on the face of the anvil, as the round horn wedges up into the metal and lengthens it, and there is less tendency for it to stretch in all directions. If a piece tends to get too wide it may be placed on edge and hammered.

Hammering after the red heat leaves is hard work and accomplishes little. Also, the iron is apt to split or crack if hammered too cold.

Drawing Round Rods.-To make a round rod smaller, the following steps should be carefully followed.

1. Make it four-sided, or square in cross section.2. Draw it to approximately the desired size while it is square.

3. Make it distinctly eight-sided by hammering on the corners after it is drawn sufficiently.

4. Make it round again by rolling it slowly on the anvil and hammering rapidly with light blows or taps.

An attempt to draw round rods without first going to the square section not only requires a lot of extra work but usually results in a badly distorted and misshaped piece.

Pointing a Rod.-If a round point is desired on a rod, a square tapered point should first be made. It is then easy to make it eight-sided and finally round.

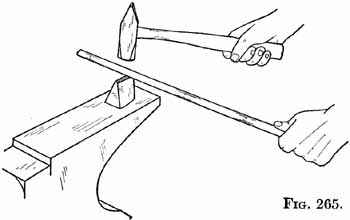

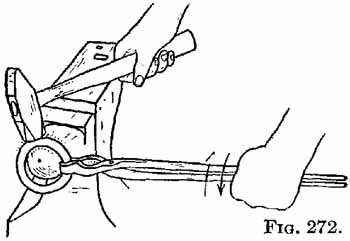

In making a point the rod should not be held flat on the anvil, but the back end should be raised somewhat. Also, the hammering should be done with the toe of the hammer lower than the heel, so that the desired angle for the point is formed between the hammer face and the anvil. The hammering should be done on the far edge of the anvil, so that the toe of the hammer will not leave marks in the anvil face.

293. Upsetting.-Upsetting is simply the reverse of drawing, or the process of making a piece shorter and thicker. It is done when more metal is needed to give extra strength, as when a hole is to be punched for an eye. There are two main points to be observed in upsetting:

1. Heat the bar or rod to a high red or nearly white heat throughout the section to be upset.2. Strike extremely heavy well-directed blows.

Light blows simply flatten and burr the end instead of upsetting the piece throughout the heated section. The extra-heavy blows needed for upsetting can best be struck by first striking A light blow or two to get the direction of striking and then following with an extra-hard blow.

Probably the best way to upset a short piece is to place the hot end down on the anvil and strike the cold end. The hot end, of course, may be up, but it is usually easier to upset without bending if the hot end is down. If the bar starts to bend it should be straightened at once. Further hammering will simply bend it more instead of upsetting it.

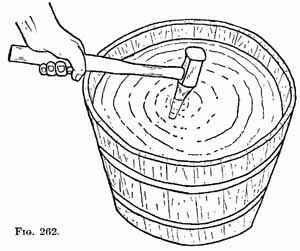

In order to heat thoroughly the part to be upset, and yet confine the heat to this part, it is sometimes better to heat the work somewhat further than the upsetting is to go and then cool it quickly back to the line of upsetting by dipping in the water.

The end of a long bar may be upset by laying it on the anvil face with the hot end projecting beyond the edge, and striking heavy blows endways with the hammer. If the bar is long and heavy enough, it may be upset easily by ramming the hot end against the face or the side of the anvil.

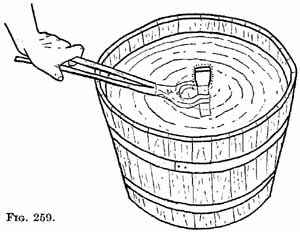

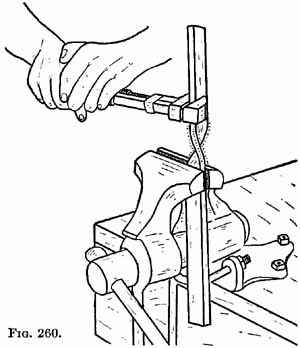

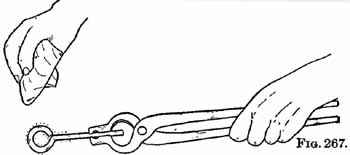

294. Twisting.-Twisting is really a form of bending. Small pieces may be twisted by heating the section to be twisted to a uniform red heat, clamping a pair of tongs at each end of the section and applying a turning or twisting force. If the piece is too large to be twisted this way (say more than about 1/4 in. thick by 1 in. wide), it may be clamped in a vise and twisted with a pair of tongs or a monkey wrench, the jaws of the vise and the wrench being carefully placed at the ends of the section to be twisted. It is important that the work be done rapidly before the iron cools too much. For a uniform twist, the iron must be at a uniform temperature.

If the twist must be confined to a very definite section of the stock, it is a good plan to place center-punch marks at the ends of the section before the iron is heated.

Care must be exercised in twisting so as not to get the piece out of ,alignment. If it becomes necessary to straighten the bar after twisting, it may be done by striking with a wooden mallet, rather than a hammer, in order to prevent marring the sharp corners of the twisted part.

295. Punching Holes.-It is sometimes easier to punch a hole in a piece of iron than to drill it; and for some purposes a punched hole is better. For instance, in forming an eye on the end of a bar in making a hook or a clevis, punching makes a stronger eye. A small or medium.size hole is first punched and then expanded by driving the tapered punch on further through the hole, first from one side and then the other. Thus less material is wasted than if the hole were drilled, and a stronger eye results.

The steps in punching a hole in hot iron are as follows:1. Heat the iron to a good working temperature, a high red or nearly white heat.

2. Place the hot iron quickly on the flat face of the anvil-not over the pritchel hole or hardy hole. Punching over a hole would stretch and bulge the iron.

3. Carefully place the punch where the hole is to be and drive it straight down into the, metal with heavy blows until it is about two-thirds of the way through.

4. Turn the iron over and drive the punch back through from the other side. Reheat the iron and cool the punch if needed. The punch should be carefully located so as to line up with the hole punched on the other side.

5. Just as the punch is about to go through, move the piece over the pritchel hole or hardy hole to allow the small pellet or slug to be punched out.

6. Enlarge the hole to the desired size by driving the punch through the hole first from one side and then the other. Always keep the metal at a good working temperature, reheating as may be necessary.

A. Carefully locate the punch and drive it about two-thirds of the way through.

B. Then turn the iron over and drive it back through from the other side.

C. Finally move the piece over the pritchel hole or hardy hole to allow the slug or pellet to be driven through.

The end of the punch should be dipped in water frequently to keep it from getting too hot. A little powdered dry coal dropped into the hole will help to keep the punch from sticking.

Most beginners have difficulty in placing the punch so as to get the hole centered in a bar. If, in placing the punch, it is found to be off center, it may be leaned and twisted slightly until it is in the correct position. In punching hot iron, it is much better to use a punch with a handle in it, as it is uncomfortable to hold a short punch on a red-hot bar.

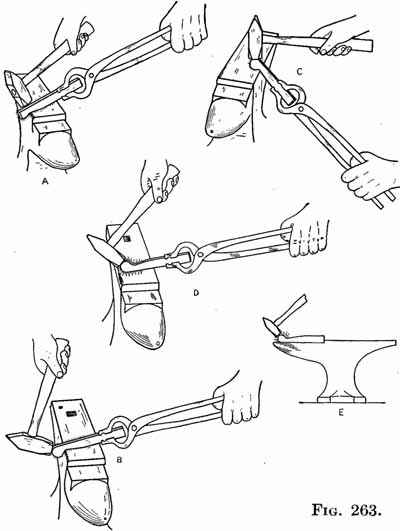

296. Forming Punched Eyes.-Usually, although not always, when a hole is to be punched for an eye, as in a chain hook or a clevis, it is best to upset the stock first so as to give more metal and make a stronger eye.

After upsetting, the end is shaped and the corners are rounded before punching. This can best be done by forming a neck or shoulder just -back of the eye by hammering over the far edge of the anvil, as shown in Fig. 263A. The end is then further shaped and the corners rounded by working over the anvil as suggested in the various other views of Fig. 263. Having the end thus shaped, the hole may be punched in the usual fashion.

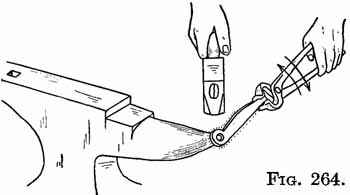

In a clevis, the holes are punched with straight sides to fit the clevis pin. For holes in chain hooks, however, it is desirable to have the edges and corners rounded. This can be done by placing the eye at an angle on the end of the horn and making the stock approximately eight-sided and then finally round by rolling slowly while striking light, rapid blows (see Fig. 264).

297. Cutting with the Hardy.- The blacksmith does most of his cutting of iron and steel on the hardy rather than with a hack saw. Although the hardy does not leave quite so smooth a cut as a saw, it is quite satisfactory for most work. It cuts faster and easier than a saw and is less expensive to use, as there are no blades to wear out or break.

To use a hardy, the rod or bar to be cut is simply placed on it and hammered down against the sharp edge. Hardies may be used for either hot or cold cutting. Some smiths prefer to keep two hardies, one that is thick and stocky and tempered for cutting cold iron and one that is thin for, cutting hot iron. The hardy, like any other Cutting tool, works much better if kept sharp. It may be ground like a cold chisel.

In cutting cold iron, the bar may be deeply nicked on two or more sides and then broken off by bending. In cutting hot iron, it is common practice to cut clear through from one side. Care must be taken, of course, not to let the hammer strike the cutting edge of the hardy, or else both the hammer and the hardy may be damaged. In finishing a cut, the last two or three blows should be struck just beyond the cutting edge and not directly over it.

Cutting Tool Steel.-No attempt should be made to cut tool steel in the hardened state. It should always be annealed or softened. To cut it on the hardy, it should be cut hot-not cold-and handled just like other iron or steel.

Where it is important to have a smooth cut, a bar of tool steel may be sawed about a quarter of the way through and then broken by clamping in a vise at the sawing line and hammering (see Art. 212, page 146).

298. Estimating Amount of Stock Required.-To estimate the amount of stock required for bends and curves, estimate the length of the center line. For example, suppose it is desired to know how much will be needed for making a ring of 1/2-inch round stock and of 3 in. inside diameter. The length needed will be the length of the mid-line, halfway between the inside and the outside edges. Its length is equal to the mid-diameter, 3 1/2 in. times 3.1416, or 11 in.

To determine the length required for pieces of irregular shape, small wire can be bent into the desired shape and then straightened out and measured.

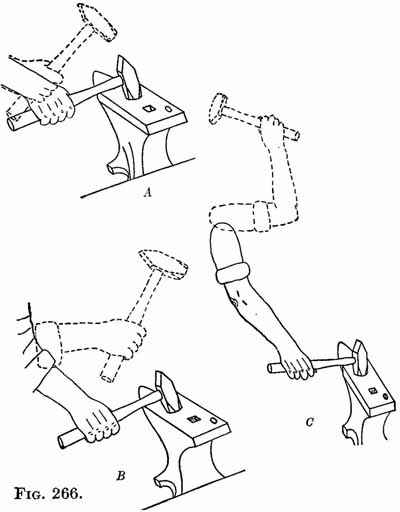

299. Striking with the Hammer.-Success in blacksmithing depends largely upon ability to strike effectively with the hammer. Most blacksmithing requires heavy, well-directed blows. Where light blows are better, however, they should be used.

Light blows are struck mostly with motion from the wrist; while heavier blows require both wrist and elbow action; and very heavy blows require action from the shoulder in addition to wrist and elbow motion.

To direct hammer blows accurately, strike one or two. light taps first, to get the proper direction and feel of the hammer, and then follow with quick, sharp blows of appropriate force or strength. It is also important to use a hammer of appropriate size. A heavy hammer on light work is awkward, and blows cannot be accurately placed. And using a light hammer on heavy work is very slow and tedious.

300. Blacking.-After forging a piece of iron it is a good plan to black it by heating it slightly and rubbing with an oily rag. The iron should not be red, yet it should be hot enough to burn the oil off and prevent a greasy appearance. Blacking the piece gives a better appearance and provides some protection against rusting. Tempered tools, of course, should not be blacked in this manner, as heating will draw the temper.

Fig. 266.-Striking with the hammer.

A. Light blows are struck largely with wrist motion.B. Moderate blows require both elbow and wrist action.

C. Heavy blows require shoulder action as well as wrist and elbow motion.

Points on Blacksmithing 1. A clean, deep, compact fire is the first requirement for good blacksmithing.

2. Put the irons in the fire in a horizontal position-never point them down into the fire.

3. Use tongs that fit the work. If they do not fit, heat them and reshape the jaws over the piece to be held.

4. Always work the irons at a good forging heat-a bright red or nearly white heat for mild steel.

5. Never allow the irons to get hot enough to sparkle, except in welding, and even then very little.

6. In bending, use bending or leverage blows-not mashing blows.

7. In drawing, strike square, direct blows straight down-not forward-pushing, or glancing blows.

8. In drawing round rods, always make them square first and do the drawing while square. When drawn sufficiently, make them eightsided and finally round.

9. To smooth up a round rod, roll it slowly on the anvil while striking a series of light, quick blows.

10. In pointing rods, work on the far edge of the anvil. Raise the back end of the rod and strike with the toe of the hammer tilted down.

11. In upsetting use a high heat, and strike extra-heavy blows.

12. To make a good twist, have the section to be twisted at a uniform temperature.

13. To punch a hole in a hot iron, start in on the flat face of the anvil. Then turn it over and drive the punch back from the other side. Move the iron over a hole in the anvil face for finally driving out the pellet.

14. In cutting on the hardy, be careful not to let the hammer strike the cutting edge.

15. Use the chipping block for cutting with the cold chisel-not the flat face of the anvil.

16. To estimate the amount of stock required for curved pieces estimate the length of the mid-line.

17. Strike light hammer blows with wrist motion only; medium blows' with motion from both the wrist and the elbow; and heavy blows with motion from the shoulder, wrist, and elbow.

18. Blacking a forging gives it a better appearance and provides some protection against rust. To black, simply rub the piece with an oily rag when it is just hot enough to make the rag smoke.

Questions 290. (a) What are the main fundamental forging operations? (b) Why is it important to master them thoroughly? (c) What are the main important points to observe in bending iron at the anvil? (d) How may irons be bent without mashing them? (e) How may square bends be made without marring or galling the iron? (f) How may irons be straightened? (g) What procedure would you use for bending flat irons edgeways?

291. (a) Explain and be able to demonstrate the procedure for making an eye on the end of a rod. (b) If an eye is somewhat oval in shape, how may it best be rounded? (c) Why is it important to keep the iron at a high forging heat?

292. (a) What is drawing? (b) What are the main important points to be observed in drawing? (c) When, if ever, should forward pushing blows be used in drawing? (d) What difficulties may arise from hammering the iron too cold? (e) What are the steps in the process of drawing round rods? (f) In making a tapered point, why should the iron not be laid flat on the anvil? (g) Why should the hammering be done on the far. edge of the anvil face? (h) Why should the toe of the hammer be lower than the heel?

293. (a) What is upsetting and for what purposes is it done? (b) Why should very heavy blows be used in upsetting? (c) How may a very high heat be used and yet confined to only the portion to be upset? (d) What special ways may be used for upsetting the end of a long heavy bar?

294. (a) How may a twist be neatly made in a bar and confined to a definite part of the bar? (b) Why is a uniform heat especially desirable for twisting? (c) Why is it important to work rapidly in twisting?

295. (a) What advantage is there to be gained by punching a hole rather than drilling it? (b) Just what procedure should be used in punching a hole? (c) Why should the hole be started on the flat face of the anvil rather than over the pritchel hole or hardy hole? (d) How may the punch be kept from sticking in the hole? (e) How may a punch be maneuvered to get it located exactly in the desired position for punching?

296. (a) Just how can a head or shoulder be formed on the end of a bar preparatory to making a punched eye? (b) How may the eye for a chain hook have the corners and edges rounded after the hole is punched?

297. (a) What advantages does cutting with a hardy have over hacksawing? (b) What points should be observed in cutting with a hardy? (c) Can tool steel be cut on a hardy? If so, just how?

298. (a) How may the amount of stock required for a ring be closely estimated? (b) How may the amount of stock required for irregular bends and curves be estimated?

299. (a) Explain and be able to demonstrate just how to hold the hammer and strike light blows; also medium blows and heavy blows. (b) What difficulties may arise from using a hammer that is too heavy or too light for the work at hand?

300. (a) How may irons be blacked after forging? (b) How hot should they be for blacking? (c) What are the purposes of blacking? (d) May tempered tools be blackened in the same, manner as ordinary mild steel?

References SCHWARZKOPF: "Plain and Ornamental Forging."

RADEBAUGH: "Repairing Farm Machinery."

FRIESE "Farm Blacksmithing."

HARCOURT: "Elementary Forge Practice."

Boss, DENT, and WHITE: "Mechanical Training."

SMITH ROBERT H.: "Agricultural Mechanics."

SELVIDGF, and ALLTON: Blacksmithing.

CHAPTER XX

FORGING AND TEMPERING TOOL STEEL

One of the main advantages of having a forge in the farm shop is to be able to redress and make and temper tools like cold chisels, punches, screw drivers, picks, wrecking bars, etc. Tool steel for making cold chisels and punches and similar tools may be bought from a blacksmith or ordered through a hardware store; or it may be secured from parts of old machines, such as hay rake teeth, pitchfork tines, axles and drive shafts from old automobiles.301. Nature of Tool Steel.-Tool steel contains more carbon than mild steel, and it is granular, while mild steel is fibrous or stringy (see Art. 328, page 242). The smaller the size of the grains or particles in tool steel, the tougher and stronger it is. When tool steel is heated above a certain temperature, called the critical temperature, the grain size increases. (The critical temperature is usually between 1300 and 1600 F., depending upon the carbon content, and for practical purposes is indicated by a dark-red color.) If the steel is heated only slightly above the critical temperature, the fine grain size may be restored by allowing it to cool slowly and then reheating it to just the critical temperature. If the steel is heated to a white heat, however, the grain size will be permanently enlarged and the steel damaged or possibly ruined. If tool steel is hammered with heavy blows while it is just above the critical temperature, the grain size will be made smaller, and the steel thereby refined and improved. It is evident, therefore, that a piece of steel may be improved or damaged or even ruined, depending upon how it is heated and forged.

302. Heating Tool Steel.-Tool steel should be heated slowly and evenly in a good, clean, deep, coke fire. Uneven heating, which is usually caused by heating in poor shallow fire or by too rapid heating, results in unequal expansion, which in turn may cause internal cracks and flaws.

Tool steel should not be heated above a bright-red or low-orange heat, and to this temperature only for heavy hammering. Heating higher is likely to ruin the grain structure. In case a piece of steel is accidentally heated a little too hot, the grain size may be restored by (1) allowing it to cool slowly and then reheating, being careful not to overheat it again, or (2) by heavy hammering at a bright-red or low-orange heat. The damage done by overheating will depend upon the temperature to which it was heated, how carefully it is subsequently heated and handled.

303. Forging Tool Steel.-Since the making of a satisfactory tool depends so largely upon the proper heating and handling of the steel, the following points should be kept in mind when forging with it.

1. Tool steel has a much narrower range of forging temperatures than mild steel. Hammering below a red heat may cause cracking or splitting, while temperatures above a bright red or dark orange may damage the grain structure.2. Tool steel should always be uniformly heated throughout before it is hammered. Otherwise the outside parts, which are hotter, may stretch away from the inside parts, which are colder, and thus cause internal flaws.

3. Very light hammering should be avoided, even when the steel is well heated, because this may likewise draw the outer surface without affecting the inner parts.

4. As much of the forging as possible should be done by heavy hammering at a bright-red or dark-orange heat--slightly above the critical temperature-as this will make the grain size smaller and thus refine and improve the steel.

5. When a piece is being finished and smoothed by moderate blows, it should not be above a dark-red heat.

304. Annealing Tool Steel.-After a tool has been forged, it is best to anneal it, or soften it, before hardening and tempering. This is to relieve' any strains that may have been set up by alternate heating and cooling and by hammering. Annealing is done by heating the tool to a uniform dark-red heat and placing it somewhere out of drafts, as in dry ashes, or lime, and allowing it to cool very slowly. (Copper and brass may be softened by heating to a red heat and plunging quickly into water.)

305. Hardening and Tempering Tool Steel.-If tool steel is heated to a dark red, or the critical temperature, and then quenched (cooled quickly by dipping in water or other solution), it will be made very hard,the degree of hardness depending upon the carbon content of the steel and the rapidity of cooling. The higher the carbon content, the harder it will be; and the more rapid the cooling, the harder it will be.

A tool thus hardened is too hard and brittle and must be tempered, or softened somewhat. This is done by reheating the tool to a certain temperature (always below the hardening temperature) and quickly cooling it again. The amount of softening accomplished will depend upon the temperature to which the tool is reheated. For practical purposes the farm shop, these temperatures are judged by the color of the oxide or scale on the steel as it is being reheated. A straw color, for example, indicates that the tool has been reheated to a comparatively low temperature, and if quenched on a straw color, it will be rather hard. A blue color, on the other hand, indicates that the tool has been reheated considerably higher, and, if quenched on a blue, it will be softer.

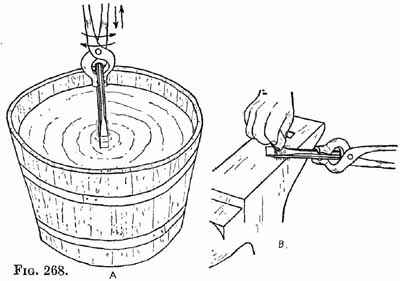

306. Hardening and Tempering a Cold Chisel.-After a cold chisel is forged and annealed, it may be hardened and tempered as follows:

1. Heat the end to a dark red, back 2 or 3 in. from the cutting edge.2. Cool about half of this heated part by dipping in clean water and moving it about quickly up and down and sideways, until the end is cold enough to hold in the hands.

3. Quickly polish one side of the cutting end by rubbing with emery cloth, a piece of an old grinding wheel, a piece of brick, or an old file.

4. Carefully watch the colors pass toward the cutting end. The first color to pass down will be yellow, followed in turn by straw, brown, purple, dark blue, and light blue.

5. When the dark blue reaches the cutting edge, dip the end quickly into water and move it about rapidly. If much heat is left in the shank above the cutting edge, cool this part slowly so as not to harden the shank and make it brittle. This is don by simply dipping only the cutting end and keeping it cool -while the heat in the shank above slowly dissipates into the air.

6. When all redness has left the shank drop the tool into the bucket or tub until it is entirely cool.

Fig. 268.-Tempering a cold chisel. A. The end is heated to cherry red back about 3 in. from the cutting edge. Then about half the heated portion is cooled in clean water, moving the tool about rapidly, up and down and sideways, to prevent too sharp demarcation between the hot and cold parts.B. The end is then quickly polished by vigorous rubbing with emery cloth or other abrasive to enable the colors to be seen as they pass down. When a dark blue appears at the cutting edge, the end of the tool-and only the end-is again dipped, working it up and down and around, and keeping it cold while any heat in the shank of the tool is slowly given up to the air.

When the tool is first dipped, it is important that it be moved up and down to prevent the formation of a sharp line between the hardened and unhardened parts, as such a line might cause the tool to break at this point sometime later when in use.

If the colors come down too rapidly, the tool may be dipped into the water and out again quickly to retard their movement. When they move down slowly it is easier to watch them and do a good job of tempering.

Dipping the end at the first of the hardening and tempering process makes it very hard. The heat left up in the shank of the tool, however, gradually moves down to the cutting end and softens it; and when it is softened to the desired degree of hardness, as indicated by the color, the tool is then quickly quenched to prevent any further softening. The various colors are simply indications of different temperatures.

If a tool is tried and found to be too soft, a as indicated by denting, it should be retempered and the final quenching made before the colors have gone out quite as far as they did originally-that is, before the end has been softened quite as much. In case a tool proves to be too hard and the edge chips or crumbles, it should be retempered and the colors allowed to go out a little further.

307. Tempering Punches, Screw Drivers, and Similar Tools.-Tools like punches, screw drivers, scratch awls, etc., may be tempered in the same manner as a cold chisel, but may be made harder or softer according to the requirements of the tool. A scratch awl should be made somewhat harder than a cold chisel, a rock drill somewhat harder, a center punch just a little harder, a punch for lining up holes somewhat softer, a screw driver somewhat softer, etc.

Different grades of tool steel will have different degrees of hardness when quenched at the same color. Therefore, it may be necessary to experiment a little with the first piece of a new lot of steel in order to secure the desired degree of hardness.

308. Tempering Knives.-Knives and tools with delicate parts are usually hardened and tempered in a manner slightly different from that used for cold chisels, in order to avoid the danger of overheating and warping and to insure uniform hardening and tempering of the cutting edges.

After a knife is forged, it should be annealed. It is then heated slowly and uniformly to a dark red, or the critical temperature. It is then quickly cooled by dipping edgeways in clean tepid water or oil, thick edge first. This method of dipping helps to insure uniform cooling and therefore uniform hardening and freedom from warping. It is then polished and reheated by drawing it back and forth through a flame, or by laying it against a large piece of red hot iron and turning it frequently to insure uniform heating. When the desired color, usually blue, appears, it is again quickly cooled.

Another method of heating knives and similar tools for hardening and tempering is to draw them slowly back and forth inside a pipe in the forge fire. The pipe should first be uniformly heated in a big fire and then turned frequently to keep it uniformly heated on all. sides. The knife should not be allowed to touch the pipe.

Points on Forge and Tempering Tool Steel 1. Use a good, clean, deep, coke fire for heating tool steel and heat it slowly and evenly.2. Heating in a poor shallow fire, or heating too rapidly, is likely to cause uneven heating, which results in unequal expansion, which in turn may cause internal flaws or cracks.

3. Proper hammering of tool steel at the proper temperature refines it, making the grain size smaller.

4. Do riot hammer tool steel unless it is at least at a dark-red heat, and heated uniformly clear through.

5. Hammering below a red heat is likely to cause cracking and splitting.

6. Hammering when not heated clear through may cause the outer parts to stretch away from the inner parts and cause internal flaws or cracks.

7. Light hammering should be avoided even when the steel is well heated, because of danger of drawing the outer surface without affecting the inner parts.

8. Never heat tool steel above a bright-red or low-orange heat, and then only for heavy hammering.

9. For moderate hammering, as in finishing and smoothing a job, do not heat above a dark red.

10. Tool steel is ruined if it gets white hot.

11. In case tool steel is accidently overheated somewhat, allow it to cool slowly and then reheat, being careful not to overheat it again; or heat it to a bright-red or low-orange heat and forge by heavy hammering to restore the fine grain size.

12. After a tool is forged, it should be annealed by heating to a uniform low red and placing it in dry ashes or similar material to cool slowly.

13. In quenching a tool like a cold chisel, move it about rapidly-up and down and around-to prevent a sharp line of demarcation between the hot and cold parts.

14. Tempering colors should move slowly so they may be easily seen. If they move too fast, dip the tool quickly into water for an instant.

15. In the final quenching of a tool like a cold chisel, cool the end quickly but dissipate any, heat left in the shank very slowly. Otherwise the shank may be hard and brittle.

16. In case a tool is found to be too hard, retemper it and allow the temper colors to go out a little further before final quenching.

17. In case the tool is too soft, quench before the colors go so far.

Questions 301. (a) What materials may usually be obtained about the farm for making tools like cold chisels, punches, and screw drivers? (b) What are the chief differences, in chemical composition and physical properties, between tool steel and mild steel? (c) What is the critical temperature of tool steel? (d) How may the smith recognize it? (e) How may tool steel be so hammered as to refine it?

302. (a) Why should tool steel not be heated too rapidly? (b) What i's the highest safe forging heat for tool steel? (c) What trouble will occur if tool steel is overheated? (d) What should be done in case tool steel is accidentally overheated?

303. (a) What troubles may develop from hammering tool steel below a red heat? (b) What trouble may develop from hammering when it is not uniformly heated throughout, or from hammering with very fight blows? (c) What is the best heat for heavy hammering of tool steel? For moderate or finish hammering?

304. (a) What is annealing? (b) Why should a piece of tool steel be annealed after it is forged? (c) Just what is the procedure for annealing?

305. (a) How may tool steel be hardened? (b) What determines the degree of hardness to which a piece of tool steel may be hardened? (c) What is tempering? (d) How may tool steel be tempered?

306. (a) Explain and be able to demonstrate the process of hardening and tempering a cold chisel. (b) Name the colors in the order in which they appear at the end of the chisel. (c) Why is it important that the end of the chisel be moved about rapidly in the water at the first quenching? (d) Why is it important that only the cutting end be cooled quickly at the second quenching, and that the shank be cooled slowly? (e) Why is it desirable to have the colors move down slowly? (f) What would you recommend, if upon trial it is found that a cold chisel has been tempered too hard? If too soft?

307. (a) In what respects are tools, like punches, scratch awls, and screw drivers, tempered differently from cold chisels? (b) How should the hardness of the following tools compare with that of a cold chisel? Scratch awl? Screw driver? Rock drill? Center punch?

308. (a) Why are knives and similar tools not hardened and tempered in the same manner as cold chisels? (b) Outline, step by step, a good method of hardening and tempering a knife. (c) In quenching a knife, which part is immersed first? Why?

References SCHWARZKOPF: "Plain and Ornamental Forging."

BURGHARDT: "Machine Tool Operation." Part I.

RADFBAUGH: "Repairing Farm Machinery."

FRIESE: "Farm Blacksmithing."

HARCOURT: "Elementary Forge Practice."

Boss, DENT, and WHITE: "Mechanical Training."

SMITH, ROBERT H.: "Agricultural Mechanics."

SELVIDGE and ALLTON: "Blacksmithing."

CHAPTER XXI

WELDING

PLOW SHARPENING

KINDS OF IRON AND STEEL

WELDING

309. The Welding Fire.-A good fire is the first requirement for welding. It is important for any blacksmithing work, but for welding it is indispensable.The fire must be clean, that is, free from clinkers, brass, babbitt, etc., as such impurities tend to make the irons slippery instead of sticky at the welding temperature. Lots of good coke is needed, as fresh coal not only makes a smoky fire but may also introduce some sulphur, which will make welding difficult, if not impossible.

The fire should be deep, with at least 4 in. of burning coke below the irons. There should also be burning coke on both sides and above the irons. Thus enough heat can be provided for thorough heating of the irons before the fire burns down.

The fire should be compact and well banked with dampened coal so as to confine. and concentrate the heat and to prevent too much air from going through the fire and causing the irons to oxidize or scale unduly.

The fire should be thoroughly cleaned about every half hour while welding.

310. Scarfing the Irons.-Ends to be welded together should first be properly shaped or scarfed. Scarfed ends should be short, usually not over 1 1/2 times the thickness of the stock; and they should have rounded or convex surfaces, so that when they come together any slag or impurities will be squeezed out rather than trapped in the weld. Long, thin, tapering scarfs are to be avoided because they are easily burnt in the fire and because they cool and lose their welding heat very rapidly when removed from the fire, thus making welding exceedingly difficult.

In order to counteract the wasting away of the irons by scaling and the tendency to draw out from hammering when they are welded, the ends are commonly upset before scarfing. Scarfs on the ends of bars are made by working on the far edge of the anvil, striking backing-up or semi-upsetting blows with the toe of the hammer lower than the heel. (See Art. 314, page 235, for instructions on the link scarf.)

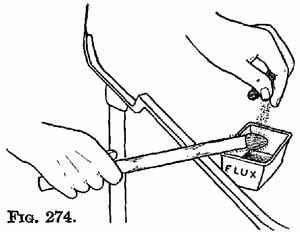

311. Welding Flux.-Borax or clean sand, or a mixture of the two, may be used as a welding flux. Commercial welding flux, however, such as may be bought from hardware stores, is usually more satisfactory; and since but a little is needed, it is probably best to buy a small package for the farm shop.

Flux is applied to the pieces to be welded after they are at a red or white heat and just before the welding heat is to be taken. It covers the irons and causes the oxide to melt at a lower temperature. The oxide must be melted before the irons can be welded.

Flux is not needed in welding wrought iron, as it may be heated above the melting temperature of the oxide without danger of burning. Although it is possible to weld mild steel without flux, it is much easier to do a good job with it. Tool steel cannot be welded without flux.

312. Heating the Irons.-The irons should be heated slowly at first, so they will heat thoroughly and uniformly throughout. The irons should be turned over once or twice during the heating to insure equal heating of all sides and parts.

After the irons reach a bright-red heat, remove them and dip the scarfed ends into flux, or sprinkle the flux on them with the fingers. Replace the irons in the fire and continue to heat, being careful not to brush the flux off the irons before it melts. Pull a few lumps of coke on top of the irons and raise the coke occasionally with the poker to see how the heating is progressing.

Care must be taken to see that both irons reach the welding heat at the same time. If one heats faster, pull it back into the edge of the fire for a few seconds. During the last part of the heating, have the scarfed sides of the irons down so they will be fully as hot as the other parts of the pieces.

313. The Welding Heat.-When the irons reach the welding temperature, they will be a brilliant, dazzling white; their surfaces will appear molten, much like a melting snowball; and a few explosive sparks will be given off. When the sparks start to come from the fire a little more violently, it is time to remove them and weld them together.

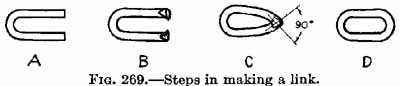

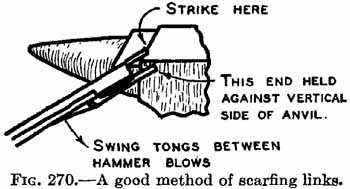

314. Welding a Link or Ring.-To make a link or ring, the stock is first heated and bent into a horseshoe or U-shape. The ends are then scarfed by placing on the anvil, with one end diagonally across the shoulder between the anvil face and the chipping block, and with the other end against the vertical side of the anvil. A series of three or four medium or light blows -are struck on the end on the shoulder, swinging the tongs a little between each blow. In this manner the end of the U is given a short, blunt, angling taper with a slightly roughened surface. The piece is then turned over and the other end scarfed in the same manner. The scarfs may be finished by striking lightly with the cross peen of the hammer.

Fig. 269.-Steps in making a link.

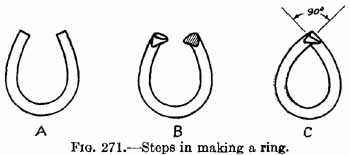

The legs of the U are next bent over the horn, lapped together, and hammered shut. It is important that the link or ring be somewhat egg-shaped at this stage-not round. The ends should cross each other at an angle of about 90 deg. This insures plenty of material at the joint for finishing the link and prevents a thin, weak section at the weld.

Fig. 270.-A good method of scarfing links.

The link is then placed in a good welding fire and heated, flux being applied after a red heat is reached. The link may need to be turned over in the fire a time or two in order to insure even heating.

Fig. 271-Steps in making a ring.

A. Bend to horseshoe shape. B. Scarf same as chain link. C. Bend egg-shaped and weld.When the welding heat is reached, the work is quickly removed from the fire, given a quick rap over the anvil to shake off any slag or impurities, and then put in place on the face of the anvil and the ends hammered together. The link is struck two or three quick, medium blows on one side, then turned over and struck on the other side.

Medium blows are used because the iron at welding heat is soft, and heavy blows would mash it out of shape. Forcing the parts firmly together is all that is required. It is essential to work fast before the iron loses the welding heat. A second or even a third welding heat may be taken if necessary to completely weld the ends down.

After the ends are welded together, the link is finished by rolling it slowly on the horn (by twisting or swinging the tongs back and forth) while hammering rapidly with light blows. In case of a large ring, the weld can best be finished by making the stock square, then eight-sided and finally round as in drawing round rods.

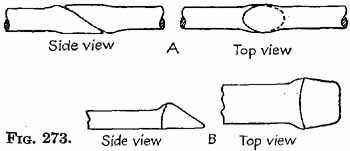

315. Welding Rods or Bars.-To weld rods or bars, it is best to upset the ends somewhat before scarfing. The scarfs should be short and thick and with rounded convex surfaces (see Fig. 273). The irons are fluxed and brought up to the welding heat in the usual manner. When they reach the welding heat, they are removed from the fire, struck quickly over the edge of the anvil to shake off any slag or impurities, put in place on the anvil and hammered together first on one side and then the other with light or medium blows, followed by heavier ones. After the first blow or two to stick the irons, the ends of the scarfs should be welded down next because they are thin and lose their welding temperature rapidly.

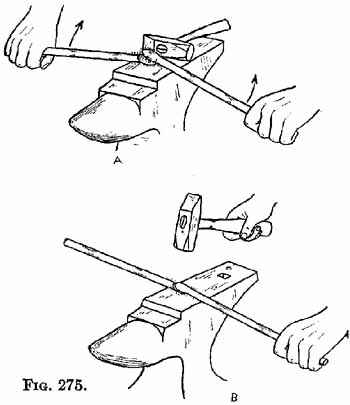

Getting Irons in Place on Anvil.-The irons are put in place on the anvil face with the scarfed surfaces together, and with the left-hand piece on top. The pieces can thus be held together with only one hand, leaving the right hand free to use the hammer. Steadying the pieces over the edges of the anvil will help get them accurately and quickly placed together (see Fig. 275).

It is a good plan for the beginner to practice bringing the irons out of the fire and placing them together a few times before taking the welding heat. Pieces that are long enough to be held in the hands without tongs are more easily handled than short pieces.

Finishing the Weld.-If it is not possible to get all parts welded down at the first heat, then flux is reapplied and another heat taken. Once the pieces are stuck well enough to hold together, however, they are much more easily handled. In welding small pieces, it is frequently necessary to take two extra heats, one on each side of the irons. In taking an extra heat to weld down a lap, the lap should be on the underside in the fire just before removing. This insures thorough heating.

After the weld is completed in a round rod, the welded section should then be smoothed and brought to size by first making the section square, as in drawing round rods, and keeping it square until drawn down to size. It is then finished by making it eight-sided, and finally round by rolling it slowly on the anvil while striking a series of light, rapid blows.

316. In Case of Failure.-If the irons do not stick at the first attempt, do not continue hammering but reshape the scarfs and try again, being sure that the fire is clean and that it is deep and compact. Irons will not stick if there is clinker in the fire, or if it has burnt low and hollow. Be sure, also, that the irons are brought well up to the welding temperature. It is generally not possible to make irons stick after two or three unsuccessful attempts because they will most likely be burnt somewhat, and burnt irons are difficult or impossible to weld. In such cases the ends should be cut off and rescarfed.

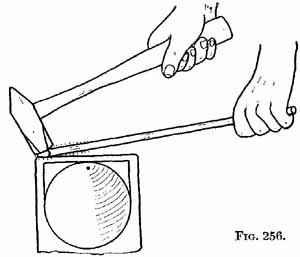

317. Welding an Eyebolt.-To make a welded eyebolt, a short, blunt, square-pointed scarf is made as shown in Fig. 276. The welding heat is taken in the usual manner, having the scarfed end down in the fire just before removing and hammering. By doing the hammering over the horn instead of the flat surface of the anvil, there will be less danger of marring and drawing the stem of the bolt next to the eye and thus making it weak at this point.

Points on Welding 1. Use a clean, deep, compact coke fire.2. Clean the fire every half hour.

3. Make the scarfs short and thick, rather than long and thin. Scarfs should not be longer than 1 1/2 times the thickness of the stock.

4. Round the surfaces of scarfs so slag will be squeezed out rather than trapped in the weld.

5. Heat the irons to a good welding heat, yet do not burn them.

6. Bring both irons up to the welding heat at the same time.

7. Have the scarfed sides of the irons down in the fire just before removing them,

8. Before welding the irons together, shake off any slag or impurities by quickly rapping the tongs against the edge of the anvil.

9. Steadying the pieces over the edges of the anvil will help get them accurately and quickly placed.

10. Strike light or medium blows when irons are at the welding heat. Simply forcing the parts together is all that is necessary. Heavy blows mash the irons.

11. Work fast; keep the hammer on the anvil within easy reach.

12. In case of failure to stick, do not continue hammering. Reflux and try again, being sure the fire is in good shape, and that you heat the irons hot enough.

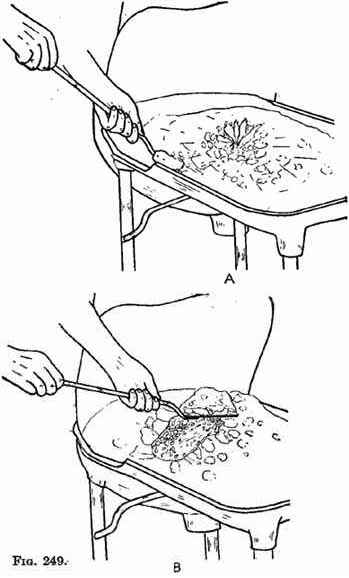

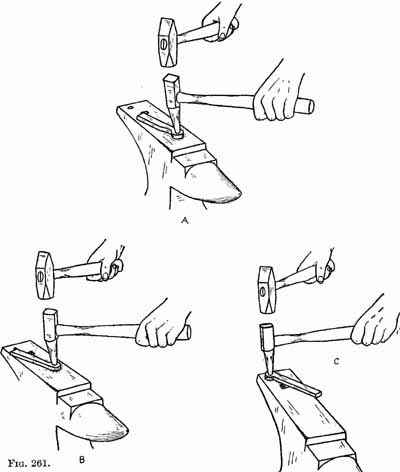

PLOW SHARPENING 318. Drawing and Shaping Steel Shares.-Steel plowshares are sharpened by heating and drawing the edge. The share should be placed in the fire so that only the portion to be drawn is heated. This is best done by placing the share flat with the edge over the center of the fire, and by banking up under the share with green coal. The share should not be placed in a vertical position with the edge down.

The share should be hammered on top, beginning at the point and working back toward the heel, beating and hammering only a small section at a time. The share should not be heated above a cherry red, and care should be exercised not to dent the top side of the share with hammer marks any more than necessary.

It is important in sharpening a share to get the point shaped so that it will have the proper suction. It should slope downward until the tip end is about 1/4 to 3/8 in. below the lower edge of the landside. The point should also be bent out toward the land slightly, usually about 1/8 to 1/4 in., to give the plow what is known as land suction. In case of a walking plow, the outer corner or wing of the share should have a small flat surface that bears on the ground and helps to support the outer side of the plow. Sulky or tractor plowshares require little or no such wing bearing.

319. Hardening the Share.-A soft-center steel share may be hardened by heating about 2 in. along the cutting edge to a dull red and then dipping it in water, cutting edge straight down. Some smiths heat the whole share to a dull red before dipping.

Solid crucible-steel shares should be hardened very little if at all. There is danger of breaking during hardening. Also, it is easy to get them too hard and brittle, which may result in breakage in use.

320. Sharpening Chilled Shares.-Chilled iron shares cannot be forged. They must be sharpened by grinding or chipping on the top side. Chilled iron shares are comparatively cheap and are commonly discarded after they are sharpened once or twice.

321. Sharpening Harrow Teeth.-Spike-tooth harrow teeth that have sharp points and sharp square edges are much more effective than teeth that have become blunt and rounded from long use. Harrow teeth are easily sharpened by forging at a cherry-red heat.

They will stay sharp longer if hardened by heating the points back from 1 to 3 in. to a dull red and dipping in water. There is some danger, however, of making them so hard and brittle that they may break in use.

KINDS OF IRON AND STEEL There are many different kinds and grades of iron and steel used in implements and other farm equipment. To be better enabled to repair such equipment, a mechanic should know something about the different kinds of iron and steel and their properties and uses.

322. Pig Iron.-The first step in the manufacture of iron and steel is to extract the iron from the iron ore, which is mined in various parts of the world. This is done by means of the modern blast furnace. The molten iron accumulates at the bottom of the furnace and is drawn off into sand molds and allowed to cool and form short, thick bars known as pig iron. Pig iron is then used as the source from which other kinds of iron and steel are made.

323. Cast Iron.-To make castings, the pig iron is remelted, together with small amounts of scrap iron, and poured into molds of the desired shape and then allowed to solidify. Cast iron is used extensively because it is cheap and can be readily molded into complicated shapes. It is hard and brittle and cannot be bent. It cannot be forged or welded in the forge fire, but it can be welded with the oxyacetylene torch. It crumbles when it is heated to a bright red or white heat. It can be drilled and sawed easily and also filed easily after the hard outer shell is removed. The quality of cast iron can be controlled by varying the amounts of scrap iron and steel mixed with pig iron when it is melted.

324. Chilled Iron.-Chilled iron is cast iron that has been made in special molds, sometimes water-cooled molds, that cool the outer portions of the casting rapidly, thus making the surface of the casting very hard and wear resistant. Chilled iron is used for bearings on certain farm machines and for shares and moldboards of plows that are to be used in gravelly or stony soils.

325. Malleable Iron.-Malleable iron is cast iron of special composition that has been treated, after casting, by heating for a long period. This prolonged heating removes some of the carbon from the surface of the casting and reduces its brittleness. Malleable castings are softer and tougher than plain castings and can be bent a certain amount without breaking. They are also more shock resistant.

326. Wrought Iron.-Wrought iron is practically pure iron with only very small amounts of carbon or impurities. It is made by removing the carbon and impurities from pig iron. The best grade of wrought iron comes from Norway and Sweden where the purest iron ores are mined. Wrought iron was formerly used extensively by blacksmiths, but, because of its high price, its use at present is quite limited. Wrought iron has about 0.04 per cent carbon.

327. Mild Steel.-Mild steel, also known variously as machine steel, low-carbon steel, soft steel, and blacksmith iron, is the common material used by blacksmiths. It is made by removing practically, but not quite, all the carbon from pig iron. To remove it all would be much more expensive. It contains from about 0.1 to 0.3 per cent carbon, not enough to enable it to be hardened to any appreciable extent by heating and quenching in water. It can be bent and hammered cold to some extent and can be forged and welded in the forge. It is a little more difficult to weld than wrought iron.

328. Tool Steel.-Tool steel is made from pig iron by first removing all the carbon and practically all the impurities and then adding a definite, known amount of carbon. Tool steel contains from about 0.5 to about 1.5 per cent carbon. It is granular in structure instead of fibrous or stringy. It must not be heated higher than a bright-red or low-orange heat, or it will become honeycombed and therefore weak and brittle. The higher the percentage of carbon the harder the steel may be tempered, an the more difficult it is to weld. Blacksmiths' tools, such as hammers and cold chisels, are commonly made of steel having from 0.5 to 0.9 per cent carbon. Taps and dies and such tools are made of steel having 1 to 1.25 per cent carbon. The carbon content of iron and steel is designated by points, one point being one-hundredth of 1 percent of carbon. Thus a 50-point carbon steel contains 50/100 or one-half of 1 per cent of carbon.

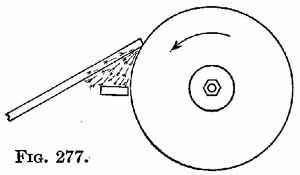

329. Distinguishing between Grades of Steel.-A good way to distinguish between the various grades of steel is to grind them on a grinding wheel and note the sparks that are given off. Sparks from wrought iron are light yellow or red and follow straight lines. Sparks from mild steel are similar but more explosive or sprangled. Tool steel gives off sparks that are lighter in color and still more explosive. The higher the percentage of carbon in steel the brighter and more explosive are the sparks.

330. Soft-center steel consists of a layer of mild steel welded between two layers of high-carbon steel. The outside surfaces can therefore be hardened, while the center remains comparatively soft and tough. It is used in moldboards of plows and in cultivator shovels where it is desired to have a very hard outer wearing surface combined with toughness and strength.

331. Alloy Steels.-Small amounts of one or more other metals, such as tungsten, nickel, chromium, silicon, vanadium, etc., are commonly mixed with steel to form alloy steels. These metals are used in steel to give certain desirable properties, such as great strength, resistance to corrosion, toughness, and resistance to shock.

Questions 309. (a) Why should the welding fire be deep, clean, and compact? (b) How often should the fire be cleaned when welding?

310. (a) What is meant by scarfing? (b) What are the characteristics of a good scarf f? (c) Why are long thin pieces hard to weld? (d) Why are irons usually upset before scarfing?

311. (a) What materials may be used for welding flux? (b) When and how is it applied? (c) Just how does a flux assist in welding? (d) What kinds of iron and steel, if any, may be welded without flux?

312. (a) What precautions should be observed in heating irons for welding? (b) What should be done in case one iron heats faster than the other? (c) Why should the scarfs be down instead of up just before the irons are removed from the fire for welding?

313. How may the welding heat be recognized?

314. (a) Outline the process of making a welded chain link or a ring. (b) What is the general shape of the link scarf ? (c) Why is it important to have the ends lapped at about 90 deg. when they are being welded? (d) Why is the link given a sharp rap over the edge of the anvil just after it is taken from the fire and before the ends are welded together? (e) Why should the weld be started with only medium and not heavy blows? (f) How may the welded part of a link or a ring be neatly and smoothly finished?

315. (a) Explain and be able to demonstrate how to quickly take two irons out of the fire and place them accurately on the anvil for welding. (b) Should the thin edges of the scarfs be welded down first or last, or at some other time? Why? (c) After a weld is completed in a round rod, just how should the welded section be neatly smoothed and brought to size?

316. (a) What are common causes of failure in welding? (b) What procedure would you recommend in case irons do not stick at the first attempt to weld? At the second or third attempt?

317. (a) Just how would you proceed to make a welded eyebolt? (b) How may the work be done to prevent marring and drawing the stem next to the eye?

318. (a) Just how should a steel. plowshare be placed in the fire for heating?, (b) How much of the share should be heated at a time? (c) What is the proper forging heat for steel plowshares? (d) Should the share be hammered on the top or on the bottom side? (e) What important points should be observed in shaping the share?

319. (a) How may plowshares be hardened? (b) What kind of shares should be hardened very little if at all? Why?

320. How are chilled iron shares sharpened?

321. (a) How are spike-tooth harrow teeth sharpened? (b) Should they be hardened? If so, how?

322. (a) What is pig iron? (b) How is it made? (c) For what is it used?

323. (a) How are castings made? (b) What are some of the important properties or characteristics of cast iron?

324. (a) What is chilled iron, and how is it made? (b) What are the main uses of chilled iron in farm machines?

325. (a) What special property does malleable iron have? (b) How are malleable castings made?

326. (a) What is wrought iron? (b) How is it made?

327. (a) How is mild steel made? (b) By what other names is mild steel commonly known? (c) What are its important properties or characteristics?

328. (a) How is tool steel made? (b) What are the chief differences between tool steel and mild steel? (c) How is the amount of carbon in tool steel commonly designated? (d) How much carbon is contained in steel used for making blacksmithing tools like hammers and cold chisels?

329. Just how may one distinguish between the various grades of steel?

330. (a) What is soft-center steel, and how is it made? (b) What are its particular advantages over other kinds of steel? (c) In what parts of farm machines is it commonly used?

331. (a) What is an alloy steel? (b) What materials or metals are commonly used in making alloy steels? (c) In what respects may allow steels be better than plain steels?

References SCHWARZKOPF: "Plain and Ornamental Forging."

RADERAUGH: "Repairing Farm Machinery."

FRIESE: "Farm Blacksmithing."

HARCOURT: "Elementary Forge Practice."

Boss, DENT, and WHITE: "Mechanical Training.

SMITH, ROBERT H.: "Agricultural Mechanics."

SELVIDGE and ALLTON: "Blacksmithing."